50 years ago on Star Trek, they had talking computers and self-diagnosing systems. While that was unbelievable and sci-fi in 1967, it is commonplace now. Many things that men and women dream of are created today by forward thinking companies.

Oil refineries are capitalizing on functionality from the Industrial Internet of Things (IIOT). IIoT is the interconnection via the Internet of technologies and computing devices embedded in everyday objects, enabling them to send and receive data. The systems and sensors can monitor, collect, exchange, analyze, and instantly act on information to intelligently change their behavior or their environment — all without human intervention.

GE coined the term “Industrial Internet” in 2012, reflecting the company’s hope that adding more sensors to machinery will result in a deluge of data that will in turn let companies squeeze more efficiency out of the equipment GE sells. It is also referred to as Industrie 4.0, Smart Manufacturing, Digitization and Connected Enterprise.

Oil refiners are no strangers to automation and data collection, but the capabilities keep expanding. To get a sense of the widening availability of features, consider how everyday consumers are getting a taste of the basic Internet of Things (IoT) with increased functionality in smart devices. With Apple’s HomeKit® you can tell your Smart Phone “Hey Siri, turn off the lights,” or use apps to check on home security while on a business trip. [Siri is a built-in “intelligent assistant” that enables users of iPhone to speak voice commands in order to operate the mobile device.] For Christmas, our company gave some of our staff the Amazon Echo Dot. They can use voice commands to play a favorite song or check traffic, or add smart thermostat’s to have Alexa (the voice assistant) adjust settings/temperature and control switches for things like fans and coffee makers.

Smart machines are better than humans at accurately, consistently capturing and communicating data.

GE is betting on IIoT by putting sensors on gas turbines, motors and other machines; connecting them to the cloud; and analyzing the resulting flow of data. The goal is to identify ways to improve machine productivity and reliability. According to MIT Sloan Management Review

“With countless number of interdependent parts, something is bound to break, fail, or decrease in performance. Entropy or the environment will somewhere create a breakdown in the system. The IIoT’s ultimate “raison d’être” [for] GE is to give everyone a heads up on what specific thing will break and when its performance will sag, so that those who make repairs can be in the right place at the right time to avoid disaster.” For example, use vibration monitoring on an FCC turboexpander to predict and schedule repair at just the right time, rather than have it randomly fail and shutdown the unit.

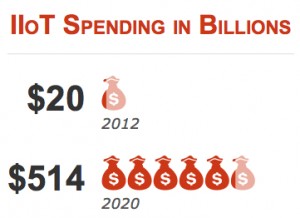

Global spending on the Industrial Internet was

Global spending on the Industrial Internet was

-$20 billion in 2012. Analysts are forecasting that number would reach

-$514 billion by 2020, creating nearly $1.3 trillion in value:

Refineries have a head start on IIoT because they have been using Distributed Control Systems (DCS), PLCs and analyzers according to Andrew Meola.

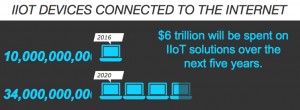

- IoT devices connected to the Internet will more than triple by 2020, from 10 billion to 34 billion. IoT devices will account for 24 billion, while traditional computing devices (e.g. smartphones, tablets, smartwatches, etc.) will comprise 10 billion.

- Nearly $6 trillion will be spent on IoT solutions over the next five years.

- Businesses will be the top adopter of IoT solutions because they will use IoT to 1) lower operating costs; 2) increase productivity; and 3) expand to new markets or develop new product offerings.

Honeywell’s approach to IIOT is 1) work collaboratively, in real time across your business 2) get the information you need in time, and in context to influence your decisions, 3) find new ways to optimize performance across your enterprise, and 4) open up new possibilities for safety, productivity, organizational responsiveness and profitability. IIoT helps a refiner connect data from over 18 different systems for better analytics and accurate key performance indicators.

Honeywell’s approach to IIOT is 1) work collaboratively, in real time across your business 2) get the information you need in time, and in context to influence your decisions, 3) find new ways to optimize performance across your enterprise, and 4) open up new possibilities for safety, productivity, organizational responsiveness and profitability. IIoT helps a refiner connect data from over 18 different systems for better analytics and accurate key performance indicators.

For Schneider Electric, IIoT can mean putting the life cycle or reliability curve of a pump into a smart drive. “When the drive sends the electricity down to the pump it knows how fast the pump should turn. If it doesn’t perform to the value it should, then the drive can actually contact somebody. It can give a note to somebody’s phone. It can pop-up an alarm on a screen. It can allow you to maximize your performance.”

According to Greg Conary, Sr VP, Head of Strategy at Schneider Electric, pumps become smart pumps. Big Data is used in the right way to get real information about the process to guide decisions in real time.

Emerson Process Management helps companies dramatically improving the speed and accuracy of decision-making and actions based on having the right information in the hands of the right expert…no matter where they sit.

“Once the … networks and sensors are in place the personnel spend less time on manual data collection, can predict failures, prioritize maintenance, optimize corrosion control and detect leaks. Personnel are usually surprised to detect so many failures when the system is turned on because it was not visible in the past. This drives maintenance activities and operations, reducing cost, downtime, losses and incidents.” Jonas Berge, Director of Applied Technology, Emerson Process Management, Singapore

Detecting vibration alone is not enough to get a complete picture of equipment health. Companies can now capture vast amounts of data from multiple devices, from multiple perspectives and easily communicate it wirelessly so that software can provide actionable predictive information. For instance, the duty of each heat exchanger bundle is trended to visualize how fouling responds to product blend and anti-fouling chemical. “The plant additionally gets the ability to pinpoint fouling and energy over-consumption, and to optimize fan speed. This drives maintenance and operations ensuring high availability at low cost, spending less time as well as reduced energy consumption etc.”

“Reliability impacts everything about a business. Top performers achieve 14% more uptime than poor performers. That equates to a lot of dollars and cents” according to Robert DiStefano www.emerson.com/en-us/asset-detail/achieving-top-quartile-reliability-returns-14044

“Reliability impacts everything about a business. Top performers achieve 14% more uptime than poor performers. That equates to a lot of dollars and cents” according to Robert DiStefano www.emerson.com/en-us/asset-detail/achieving-top-quartile-reliability-returns-14044

Douglas White of Emerson Process Management will present “Capturing Refinery Operational Value Through IIoT” at RefComm® Galveston 2017.

What IIoT initiatives are you implementing or studying? Your Sulfur Community would like to hear about them.

Wouldn’t it be great to say “Hey Siri, give me a list of all valves about to leak” or “Increase my sulfur recovery efficiency to 98%.” Now that’s an IIoT application that every Claus Plant plant would buy!

Learn more at RefComm. #REFCOMM

RefComm® Galveston 2017 and RefComm® Budapest 2017

Leave a Reply

You must be logged in to post a comment.